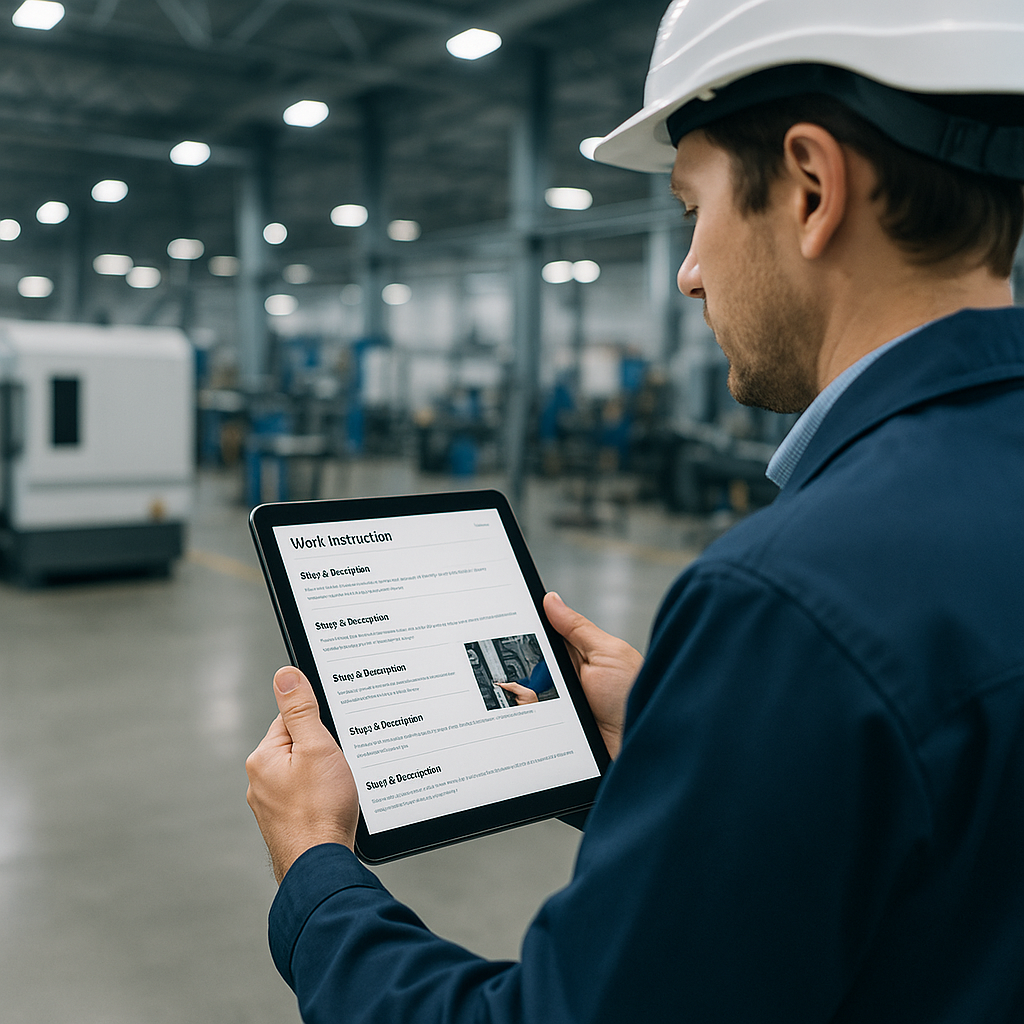

Digital Work Instructions vs. Traditional Paper Manuals

Traditional work instructions are often stored in binders or printed on paper. They're hard to update, get lost, and are rarely read. Digital work instructions, on the other hand, are:

- ✅ Instantly available on mobile and desktop

- ✅ Always reflect the latest process version

- ✅ Easier to understand thanks to images and videos

- ✅ Connected to SOPs, checklists, and data capture

- ✅ Centralized and searchable by all users

By moving to a digital system, teams reduce mistakes, downtime, and wasted effort — while improving speed and safety.